Continuous Galvanizing Line

Product name: Continuous Galvanizing Line

Category: Continuous Galvanizing Line

Process: UEC, Improved Sendzimir, Solvent Method

Coating Type: Zn, Zn-50%Al-Re, 55%Al-Zn-Si, Al-Si, Zn-Al-Mg, Zn-Al-Mg-Si

Product Specification: Width: 600-1800mm, Thickness: 0.12-4.5mm

Max. Capacity: 450,000T/A

Product introduction:

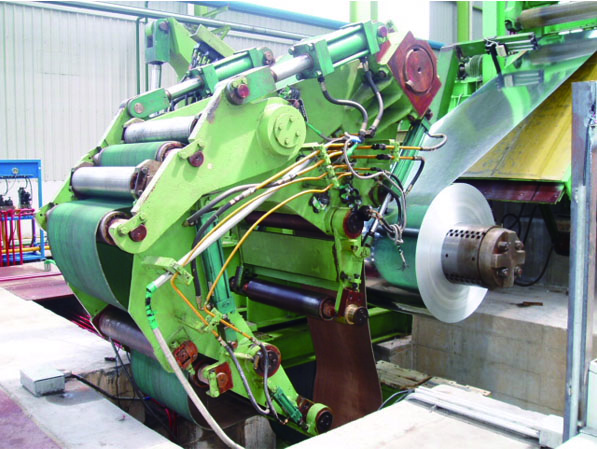

Continuous Galvanizing Line (CGL): Core Equipment for High - end Metal Anti - corrosion Coating

Efficient cleaning process: The strip steel undergoes degreasing cleaning and reducing annealing (with residual oxygen in the protective atmosphere < 10ppm to thoroughly activate the surface); the molten channel type induction zinc pot (with temperature control accuracy of ±1°C) combined with real-time monitoring of aluminum content significantly reduces zinc slag defects.

Core performance guarantee: High-speed hydrogen jet cooling (30 - 160°C/s) optimizes the mechanical properties of high-strength steel; skin pass and tension leveling improve the shape accuracy, with the surface roughness reaching Ra0.2 - 0.8, uniform zinc layer coverage (40 - 275g/1m2), and extremely strong adhesion.

Green and intelligent production: The waste heat recovery system reduces energy consumption by 10%, the modular design supports high-speed operation at 130m/min, with an annual output exceeding 300,000 tons, taking into account both efficiency and environmental protection.

Typical Achievements

Jinan Steel 250,000T/A CGL

Chongqing Panhua 350,000T/A CGL for Auto Car Plate

Zhejiang Xiehe 150,000T/A CGL

Tongsteel 350,000T/A CGL

Vietnam 120,000T/A CGL