Product introduction:

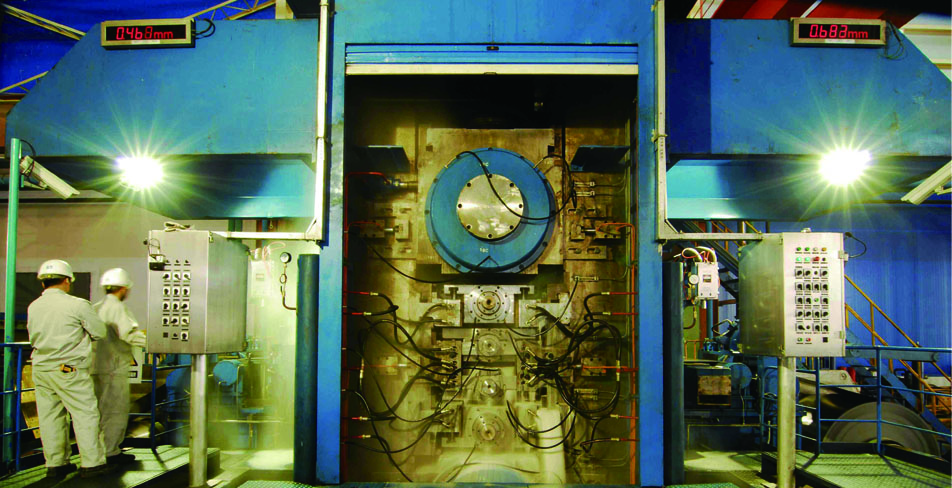

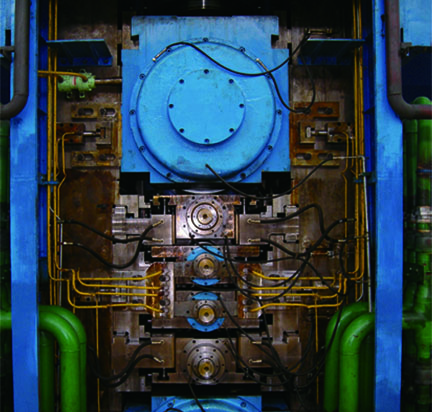

Cold Rolling Mill (CRM): Core processing equipment for high-precision metal sheets and strips

The cold rolling mill is a core device that plastically deforms hot-rolled coils or metal billets at room temperature. Through multiple passes of rolling, the material thickness is compressed to the target size (the thinnest can reach 0.15mm), and at the same time, the surface finish, dimensional accuracy, and material mechanical properties (such as yield strength) are significantly improved. Its core structure consists of a working mechanism (frame, rolls, bearings, adjustment device) and a transmission mechanism (gear box, reducer, coupling). The rolls are driven by an electric motor to apply high pressure to the strip, achieving micron-level thickness control.Application fields: Cold-rolled steel sheets have a smooth surface and excellent processing properties. They are used in home appliances such as automobiles, refrigerators, washing machines, printed iron drums, bicycles, as well as in industrial equipment, agriculture, animal husbandry, fishery, and various building materials.

Typical Achievements

Zhejiang Huada New Material Co. Ltd. 1450mm 6 High CRM

Hebei Yan Bo Coating Industry Co., Ltd. (2 sets) 1380/1100mm 6 High CRM

Wuxi Xinda China Steel Plate Company 1200mm 6 High CRM